New Energy Automobile Motor Assembly Line For Motor Rotor And Motor Stator

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Station Quantity | Appro. 20-25 Stations | Voltage | 220V, Three Phases AC |

|---|---|---|---|

| Pressing Force Range | 10kN-100kN | Station Distance | 1.5m |

| Cycle Time | 90s | ||

| Highlight | general motors assembly line,ford motor assembly line |

||

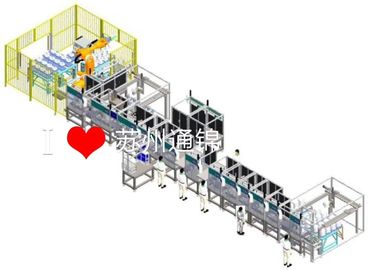

new energy automobile motor assembly line MAL series for motor rotor, motor stator and motor assembly

The workstation type automatic assembly line matches the double speed chain transportation and perfectly unifies the motor rotor, the motor stator and the motor assembly assembly, which make the production spot more regular and greatly reduce the manual pay intensity by the work pay.The new energy motor assembly line is an efficient automatic pipeline which adopts the auxiliary balance structure and the cartesian coordinate manipulator to realize the transportation and flip of the motor rotor,stator and assembly. The motor assembly line adopts the monitoring of force and displacement and cooperates with the use of safety grating ruler to bring safe and accurate automatic production.

![]()

Motor assembly line composition: assembly line body, assembly workstation, fans, pressing machine and tightening machine etc.Each 1.5 meter as a station, the entire line has about 20 stations according to the product structure.The line body driving part is composed of air pressure station, lifting platform, landing platform, upper pull rod, lower pull rod and electric. The lifting and landing platform are on two sides of the line body and are driven up and down by the cylinder, which can send the carriage car to the upper and lower line body. The upper and lower pulling rods are driven forward and backward by the cylinder and the upper claw drives the car forward.The assembly line body takes 90 seconds to complete a cycle and is interlocked and linked together with the pressing machine. Each servo pressing machine is equipped with safe grating ruler,force and displacement detection, and also provides online air tightness and static detection for the finished product to improve product quality and production efficiency and to make production safer.