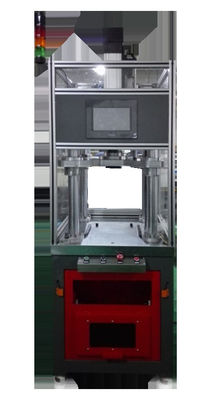

Back End Cover Servo Press Machine Touch Screen Type

| Place of Origin | China |

|---|---|

| Brand Name | TJ |

| Certification | CE |

| Model Number | TJ-SP-01,05,10,20,30,50,70,100,150,200,250,300 |

| Minimum Order Quantity | 1 pcs |

| Price | negotiable |

| Packaging Details | non wooden box |

| Delivery Time | 6~8 weeks |

| Payment Terms | T/T,30% payment in advance,70% before delivery |

| Supply Ability | 20 pcs per month |

| Name | Tongjin Servo Press Use To Press The Back End Cover Of Servo Motor | Control Forms | Touch Screen Type/computer Type |

|---|---|---|---|

| Pressure Range | 0.1~300KN | Max. Effective Stroke | 500mm |

| Pressing Mounting Speed | 0~35mm/s | Fast Forward/return Speed | 0~100mm/s |

| Max. Dwell Time | 3000s | Repeatablity | ±0.01 |

| Tongjin Servo Press Use To Press The Back End Cover Of Servo Motor | New | Warranty | Customizable |

| Highlight | 35mm/s Servo Press Machine,Back End Cover Servo Press Machine,Touch Screen Servo Press Machine |

||

Tongjin servo press use to Press the back end cover of servo motor

Main Features

1. Diverse pressing mounting modes

--meet high precision production and quality control requirements

Servo pressing machine can control pressing mounting speed,position and pressure accurately.Set lots of pressing programs including constant pressing speed,precise stop position,precise stop force,precise pressing displacement stop etc. working modes which can meet 2 or more sections pressing mounting working requirements easily.Within the stroke,we can set any stop position precisely and don’t need to use any expensive precision mould to make sure the pressing precision.The repeatability is ±0.01mm and the pressure control precision is ±1% of rated pressure.

2. Online pressing quality control

--meet quality control and data management during the whole process

(1) After the operation,all the setting,result data and press displacement curve can be shown on the interface of the pressing machine.It can control interference fit quality efficiently,realize the working data traceability management,detect and remove bad products to avoid more losses.It can also help to optimize the technical parameters and designs at the same time.

(2) With the function of checking the position upon bearing force to test whether it works and the direction is right or not.

(3)With the function of detecting the pressure and sampling other pressure values(max. value ,incremental value etc.)in any position of the pressing mounting displacement range to judge whether it can satisfy the set quality control conditions or not.

(4)With the function of detecting pressure and position in the stop position to judge whether it can satisfy the set quality control condition in the stop position.

3. Automatic precision compensation

--meet the the precise assembly requirement under the special operating condition

The servo pressing machine has unique solutions:software automatic compensation,system dynamic compensation and external trigger stop function.

Environmental,energy-efficient,safe and low operating cost

(1) The AC servo motor actuating device provides clean working environment which satisfies the special requirements of different clean workshops.

(2) Compared with pneumatic and hydraulic pressure,servo pressing mounting machine save about 80% energy,meet international environmental standard ISO14000.

4.Environmental,energy-efficient,safe and low operating cost

(1) The AC servo motor actuating device provides clean working environment which satisfies the special requirements of different clean workshops.

(2) Compared with pneumatic and hydraulic pressure,servo pressing mounting machine save about 80% energy,meet international environmental standard ISO14000.

(1) Application

The automatic shaft pressing inserting machine is special machine designed for motor shaft pressing into rotor iron core. Tongjin servo Press is suitable for automotive motor manufacturing, power tool manufacturing, household appliances motor manufacturing.

(2) Features

1.Pneumatic servo drive, adjustable within 0 to 300 tons pressure range;

2.The motor shaft is pressed into the rotor core lamination by servo power. The press-in height and the pressing force are controlled by sensors. The pressure sensor and the grating scale are equipped to accurately measure the pressure and the depression height.

3. Alarm presetting. Tongjin servo Press has the upper and lower limit alarms of the iron core height, the iron core is not pressed in place to detect the alarm, the upper and lower limits of the pressing force are detected and alarmed. When pressure or displacement goes wrong, it could be corrected timely.

4. Tongjin servo Press has automatic and manual operation, simple structure, beautiful appearance, easy operation and maintenance.

5.The rotor core thickness and the position of the pressure shaft position can be set and adjusted as needed, and the press-in depth is controlled by mechanical limit;

6. Pressing and inserting different motor rotor core shafts with replacement tooling;

7. PLC program control with LCD touch screen , allow parameter setting, display, setting press-in force, push-in depth alarm range, indicating related pressure state, set mode condition ;

8. Tongjin servo Press can automatically complete the entire work process;

9. Tongjin servo press-in quality and high production efficiency.

(3) Technical parameter

| Product name: | Tongjin servo Press: Automatic rotor shaft pressing and inserting machine |

| Stack thickness: | 20-70mm |

| Air pressure: | 0.1-30Mpa |

| Power: | 4-11KW |

| Voltage: | three-phase AC380V 50Hz/220v |

(4) Specification:

Loading/unloading: manual

Servo electric cylinder pressing(torsion mode)

Manually place shaft and stack, mechanical position limit

Pressure displacement sensor

(5) Work process

1.Automatically pre-pressing rotor shaft by servo power

2.Automatic detection of lamination thickness

3.Automatic pressure detection

4.Pressing motor shaft into the core lamination;

Pressing height, the pressing force is controlled by sensor monitoring during operation.

Product Model Definition

Example:TJ-SP-10 C T

TJ--Tongjin abbreviation

SP--Pressing machine abbreviation

10--actual pressure

01:100 KG

05:500 KG

10:1 T

100:10 T

200:20 T

C--servo pressing machine type

C:C-type

F:four-column type

D:desktop type

T--servo pressing machine control form

T:touch screen type

C:computer type

Parameters Table

| Items/Type | Unit |

TJ-SP -01 |

TJ-SP -05 |

TJ-SP -10 |

TJ-SP -20 |

TJ-SP -30 |

TJ-SP -50 |

|

|

|

Maximum value | KN | 1 | 5 | 10 | 20 | 30 | 50 |

|

Allowance range |

KN | 0.1-1 | 0.5-5 | 1-10 | 2-20 | 3-30 | 5-50 | |

|

Minimum adjustable unit |

N |

1 N |

||||||

|

Minimum detection value |

0.2% of the maximum pressure |

|||||||

|

Lead |

Maximun value |

mm | 200 | 200 | 200 | 200 | 250 | 350 |

|

Minimum adjustable unit |

mm |

0.01 |

||||||

|

Speed |

Press mounting |

mm/s | 0-35 | |||||

|

Fast forward/ return |

mm/s |

0-100 |

||||||

|

Minimum adjustable unit |

mm/s |

0.01 |

||||||

|

Dwell time |

Maximum vaule |

S | 3000 | |||||

|

Minimum adjustable unit |

S |

0.1 |

||||||

| Repeatability | mm | ±0.01 | ||||||

| Power | kw | 0.4 | 0.75 | 1.5 | 2.2 | 3.5 | 5.5 | |

| Voltage | Tri-phase | V | 380/220 | |||||

| Items/Type | Unit |

TJ-SP -70 |

TJ-SP -100 |

TJ-SP -150 |

TJ-SP -200 |

TJ-SP -250 |

TJ-SP -300 |

||||

|

Pressure range

|

Maximum value | KN | 70 | 100 | 150 | 200 | 250 | 300 | |||

|

Allowance range |

KN | 7-70 | 10-100 | 15-150 | 20-200 | 25-250 | 30-300 | ||||

|

Minimum adjustable unit |

N |

1 N |

|||||||||

|

Minimum detection value |

0.2% of the maximum pressure |

||||||||||

|

Lead |

Maximun value |

mm | 350 | 500 | 500 | 500 | 500 | 500 | |||

|

Minimum adjustable unit |

mm |

0.01 |

|||||||||

|

Speed |

Press mounting |

mm/s | 0-35 | 0-35 | 0-30 | 0-25 | 0-20 | 0-15 | |||

|

Fast forward/ return |

mm/s |

0-100 |

0-100 |

0-100 |

0-50 |

0-50 |

0-30 |

||||

|

Minimum adjustable unit |

mm/s |

0.01 |

|||||||||

|

Dwell time |

Maximum vaule |

S | 3000 | ||||||||

|

Minimum adjustable unit |

S |

0.1 |

|||||||||

| Repeatability | mm | ±0.01 | |||||||||

| Power | kw | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | ||||

| Voltage | Tri-phase | V | 380/220 | ||||||||

★Only for reference.The stroke is optional,specific parameters are subject to the agreement.

FAQ

Q:How much is your minimum order quantity?

A:1 piece.

Q:What's the price of the product?

A:The price is based on the size,specification and accessories.You can provide us the detailed information and specific requires then we will make the model selection for you and give you the formal offer.

Q:Which countries and regions do your products export to?

A:France,Germany,Italy,Brazil,Mexico,Japan,Iran,India and etc.Mainly used for motor,automobile components,bearing pressing mounting etc.By the way,many customers replace pneumatic and hydraulic pressing machines with our servo pressing machines.

Q:Can we use our own software and only buy the hardware from you?

A:Yes,of course.We will communicate with our skilled technicians to ensure the software and pressing machine do the cooperative work successfully.

| 3.Technical suggestions | |

| After-sales service | 1. Warranty Period: 12 month usually |

| 2. Overseas service center available | |

| 3. Engineers available to service overseas |