All Products

CNC Servo Driven Press Use To Press Motor Rotor Winding 35mm/S

| Place of Origin | China Suzhou |

|---|---|

| Brand Name | TJ |

| Certification | DIN EN 12020-2 |

| Model Number | TJ-SP-01,05,10,20,30,50 |

| Minimum Order Quantity | 1 pcs |

| Price | negotiable |

| Packaging Details | non wooden box |

| Delivery Time | 6~8 weeks |

| Payment Terms | T/T,30% payment in advance,70% before delivery |

| Supply Ability | 30 pcs per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Name | Tongjin Servo Press Use To Press Motor Rotor Winding, Automatic Analysis Of Product Stress Curve | Pressing Mount Speed | 0~35mm/s |

|---|---|---|---|

| Fast Forward/return | 0~100mm/s | Pressure Range | 0.1~300KN |

| Voltage | Tri-phase 380V/220VCustomized, 380V/220V Optional, 380V /220V, 220/380V, 220V/380V(According To Your Location) | Application | Hollow Cup Motor Shaft Press Mounting |

| Color | Customizable | Cnc Or Not | CNC |

| Warranty | 1 Year | Type | Semi-automatic, |

| Keyword | CNC Hydraulic Turret Punch Press | ||

| Highlight | 35mm/s Servo Driven Press,CNC Servo Press Machine,Motor Rotor Winding Servo Press Machine |

||

Product Description

Tongjin Servo Press Use To Press Motor Rotor Winding, Automatic Analysis Of Product Stress Curve

Tongjin servo press use to Press Motor rotor winding, automatic analysis of product stress curve

1.Introduction

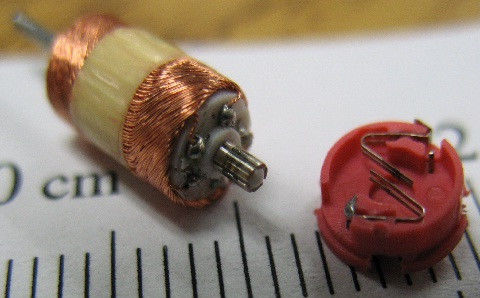

Armature winding On rotor on the motor may be simplex or multiplex and lap or wave connected. Tongjin servo press is uesed to proccess Motor rotor winding. This is mostly used in Alternator, Generator Set, Mixer Grinder, and Dc Motor.

![]()

2. Tongjin servo press in the process of pressure into the motor rotor,

Tongjin servo press in the process of pressure into the motor rotor, stator, Tongjin servo pressure function real-time display the current position and pressure equipment, installation and timely and accurately determine whether a surplus quantity size appropriate, the approximation of force and displacement at the same time show the whole pressed curve, very good solution to the traditional pressure machine can press in can't testing, universal testing machine the disadvantages of low efficiency can't mass production. But also through strengthening the design, the rigidity is far beyond the general standard of ordinary press, take the overall dustproof design.

Motor rotor, stator press installation using servo press.

| Items/Type | Unit | TJ-SP -01 | TJ-SP -05 | TJ-SP -10 | TJ-SP -20 | TJ-SP -30 | TJ-SP -50 | |

| Pressure Range | Maximum value | KN | 1 | 5 | 10 | 20 | 30 | 50 |

| Allowance range | KN | 0.1-1 | 0.5-5 | 1-10 | 2-20 | 3-30 | 5-50 | |

| Minimum adjustable unit | N | 1 | ||||||

| Minimum detection value | 0.2% of the maximum pressure | |||||||

| Lead | Maximun value | mm | 200 | 200 | 200 | 200 | 250 | 350 |

| Minimum adjustable unit | mm | 0.01 | ||||||

| Speed | Press mounting | mm/s | 035 | |||||

| Fast forward/ return | mm/s | 0-100 | ||||||

| Minimum adjustable unit | mm/s | 0.01 | ||||||

| Dwell time | Maximum vaule | S | 3000 | |||||

| Minimum adjustable unit | S | 0.1 | ||||||

| Repeatabilrty | mm | ±0.01 | ||||||

| Pov/er | kw | 0.4 | 0.75 | 1.5 | 2.2 | 3.5 | 5.5 | |

| Voltage | Tri-phase | V | 380/220 | |||||

3.Tongjin servo press functions and features:

1, can set up different press mode, to meet the diverse needs of customers.

2, brake speed separation, safe and efficient.

3, the use of pressure sensor, real-time reading data, output curve, efficient, fast, intuitive.

4, automatic recording data, can do each product fixed point tracking, convenient statistics.

5, automatic analysis of product stress curve, judge the pros and cons of products.

6, emergency stop warning mechanism, safe and reliable.

7, according to the production requirements, configure different types of press parameters.

8. The press program has password protection mode to prevent irrelevant personnel from modifying parameters without authorization.

9, real-time signal output, humanized service, convenient operation.

![]()

4. Contact us for more applications.

Contact us for more applications.

Compared with traditional press, tongjin servo press has obvious advantages in production efficiency, product quality and flexibility. The servo extrusion process can be optimized in terms of beat time, die wear, energy consumption and environmental sustainability with a powerful direct drive and accompanying control system.

Recommended Products