Precision 250KN Servo Press Machine Motor End Cover Bearing Press

| Place of Origin | China |

|---|---|

| Brand Name | TJ |

| Certification | CE |

| Model Number | TJ-SP-01,05,10,20,30,50,70,100,150,200,250,300 |

| Minimum Order Quantity | 1 pcs |

| Price | negotiable |

| Packaging Details | non wooden box |

| Delivery Time | 6~8 weeks |

| Payment Terms | T/T,30% payment in advance,70% before delivery |

| Supply Ability | 20 pcs per month |

| Name | Precision Servo Press Machine, Motor End Cover Bearing Press, | Machine Model | C-type/four-column Type/desktop Type |

|---|---|---|---|

| Control Forms | Touch Screen Type/computer Type | Pressure Range | 0.1~250KN |

| Max. Effective Stroke | 500mm | Pressing Mounting Speed | 0~35mm/s |

| Fast Forward/return Speed | 0~100mm/s | Max. Dwell Time | 3000s |

| Repeatablity | ±0.01 | ||

| Highlight | Servo Press Machine Touch Screen Type,Precision Servo Press Machine,250KN Servo Press Machine |

||

Precision Servo Press Machine, Motor end cover bearing press,

Main Features

Structural Features

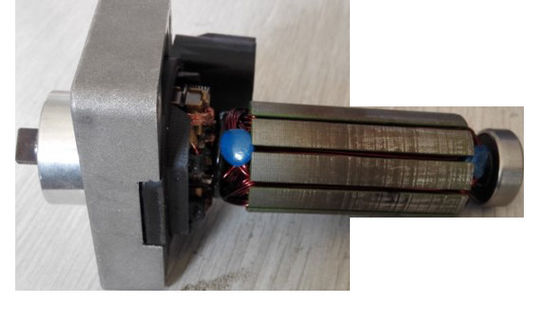

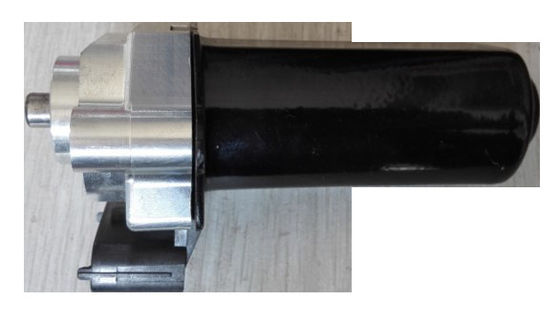

Intelligence servo pressure machine: driven by an AC servo motor, the pressure assembly and pressure displacement monitoring function are implemented through a high-precision ball screw output force. The built-in precision pressure sensor and encoder can accurately measure speed, pressure and position. The professionally developed control software can ensure that the entire process can accurately control the compression force, stop position, compression speed and holding time and other parameters, and achieve the entire process of numerical control management.

Function Application

1. Control pressing mounting assembly size precisely

Servo pressing mounting machine can test the pressure precisely according to the set pressed depth and compensate workpiece size tolerance to make sure the precision.It can also set pressure and displacement quality judgement region at the same time and detect online to ensure the product pressing mounting 100% qualified.

2. Control pressing mounting stop position precisely

(1) The guide wheels is assembled between 2 positioning pallets.The pallets need to be mounted precisely during the assembly to ensure the size.

(2) Set precise stop position and detect stop pressure.

3. Control pressing mounting time and pressure

Servo pressing machine can conduct precise regular time and pressure operation to ensure the safe and reliable bond.It is widely used in the bonding operation and the ultrasonic welding.

4. Control pressing mounting stop force precisely

The encapsulation of aluminium casing needs precise force and displacement control.Set the pressure accurately and control the stop position to avoid the motor being damaged by pressure.

Dimensions

![]()

| Model | Stroke(mm) | D(mm) | S(mm) | L2(mm) | W2(mm) | H2(mm) | L1(mm) | W1(mm) | H1(mm) |

| TJ-SP-10 | 200 | 150 | 300 | 350 | 300 | 770 | 670 | 750 | 1695 |

| TJ-SP-20 | 200 | 150 | 300 | 350 | 300 | 770 | 670 | 750 | 1715 |

| TJ-SP-30 | 200 | 200 | 400 | 450 | 400 | 770 | 770 | 900 | 1910 |

| TJ-SP-50 | 200 | 200 | 400 | 450 | 400 | 770 | 770 | 950 | 1958 |

| TJ-SP-70 | 200 | 250 | 400 | 550 | 500 | 770 | 870 | 1100 | 2095 |

| TJ-SP-100 | 200 | 300 | 400 | 650 | 600 | 770 | 970 | 1200 | 2180 |

★Only for reference.Specific parameters are subject to the agreement.

Basic Info.

| Model NO. | TJ-SP-01,05,10,20,30,50,70,100,150,200,250,300 |

| Servo Motor Power | 400W |

| Trademark | Tongjin |

| Transport Package | Wooden Box Packing |

| Specification | Parameters can customized as you need |

| Origin | China |

★Only for reference.The stroke is optional,specific parameters are subject to the agreement.