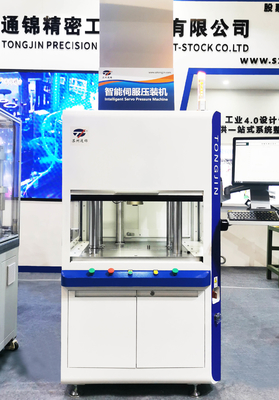

1000MPa Servo Press Machine Max Working Stroke 1000mm For Industrial Use

| Control System | PLC | Max. Working Frequency | 1000min-1 |

|---|---|---|---|

| Max. Pressure | 1000kN | Stroke | 50mm |

| Material | Steel | Weight | 1000kg |

| Max. Working Temperature | 1000℃ | Name | Servo Press Machine |

| Highlight | 1000mm Servo Press Machine,Industrial Servo Press Machine,PLC Assembly Servo Press |

||

Product Description:

The Servo Press Machine is an advanced mechanical press with a dimension of 1000mm X 1000mm X 1000mm and a maximum working stroke of 1000mm. It is equipped with a servo system, which provides precise control of press time and pressure, and data traceability and remote monitoring. It has a maximum working frequency of 1000min-1 and a weight of 1000kg. With its superior environmental protection, energy saving, safety and low operating costs, the Servo Press Machine is the perfect choice for any production line.

Features:

- Product Name: Servo Press Machine

- Dimension: 1000mm X 1000mm X 1000mm

- Type: Mechanical Press

- Max. Working Frequency: 1000min-1

- Power Supply: AC 380V

- Max. Working Stroke: 1000mm

- Data traceability and remote monitoring

- Precise control of press assembly dimensions

- High repeatability with low maintenance cost

Technical Parameters:

| Name | Value |

|---|---|

| Material | Steel |

| Power Supply | AC 380V |

| Max. Pressure | 1000kN |

| Control System | PLC |

| Max. Working Frequency | 1000min-1 |

| Dimension | 1000mm X 1000mm X 1000mm |

| Max. Working Stroke | 1000mm |

| Type | Mechanical Press |

| Max. Speed | 1000mm/s |

| Precise control of press time and pressure | Yes |

| Multiple press-mounting modes | Yes |

| Data traceability and remote monitoring | Yes |

Applications:

The Suzhou Tongjin Tj-sp-80fc servo press machine is an advanced high-performance mechanical press designed for on-line press assembly quality inspection. The machine boasts a maximum pressure of 1000kN and a maximum working stroke of 1000mm. It is equipped with a PLC control system for precise control of the pressure stop force and press stop position.

The servo press machine is made in China Suzhou and has obtained "CE Certification". It has a minimum order quantity of one and is packed in a non wooden box, with an estimated delivery time of 4-5 weeks. Payment is accepted in TT 50%. The supply ability is 800 pieces per month.

The servo press machine is suitable for a variety of industrial applications, from sheet metal forming to deep drawing. It is widely used in automotive, electrical, and electronic industries. With its user-friendly interface and powerful motor, it is an essential tool for achieving high-precision press operations.

Customization:

Our Servo Press Machine is designed with high performance and precision. It is made in China Suzhou, and has obtained the "CE Certification". The brand name is Suzhou Tongjin and the model number is Tj-sp-80fc. This machine features a max. working temperature of 1000℃, max. speed of 1000mm/s, max. pressure of 1000kN, and type of Mechanical Press. It also has on-line press assembly quality inspection, precise control of the press stop position, and multiple press-mounting modes. The minimum order quantity is 1, and the packaging details are non wooden box. The delivery time is 4-5 weeks, and the payment terms are TT 50%. We have a supply ability of 800 per month.

Support and Services:

We provide technical support and services for Servo Press Machines. Our goal is to ensure that your machines are running at optimum performance and with minimal downtime, so that you can keep your production running smoothly.

Our technical support and services include:

- Troubleshooting and repair

- Preventative maintenance

- Software updates

- Replacement parts

- Operator training

- On-site installation and support

We are committed to providing the highest level of service and support for Servo Press Machines. If you have any questions or need assistance, please don’t hesitate to contact us.

Packing and Shipping:

The Servo Press Machine is packaged in a durable cardboard box to ensure its safety during shipping. The box is then surrounded by a protective foam padding to prevent any shocks or bumps. The box is then sealed with plastic tape to keep moisture out and to ensure that the Servo Press Machine is secure during transit.

The Servo Press Machine is shipped via a reliable courier service. The courier will provide tracking information to the customer so they can monitor the progress of their shipment. All shipments are insured for full value in the event of loss or damage.