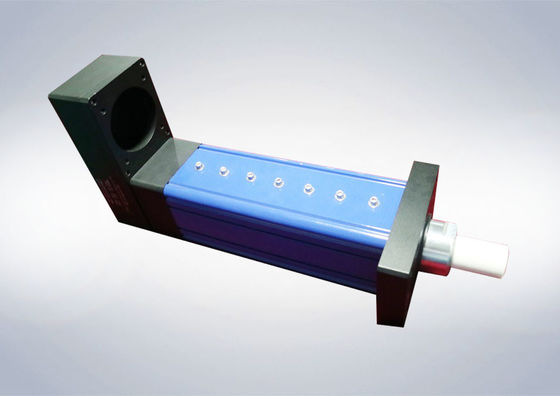

Fast Response Linear Servo Actuator With Exclusive Software 50-2000mm Stroke

| Place of Origin | China |

|---|---|

| Brand Name | TJ |

| Certification | ISO9001:2008,CE |

| Model Number | TJER190 |

| Minimum Order Quantity | 1 pcs |

| Price | negotiable |

| Packaging Details | external packing:carton or non wooden box;cushion packing:EPE foam |

| Delivery Time | 3-4 weeks |

| Payment Terms | T/T,30% payment in advance,70% before delivery |

| Supply Ability | 800 pcs per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Aluminium | Color | Standard:navy Blue&silvery,others Can Be Customized |

|---|---|---|---|

| Speed | Up To 250mm/s | Repeatability | ±0.01mm |

| Stroke | 50~2000mm | Output Force | Up To 150KN |

| Motor Connection Type | Linear/parallel | Internal Anti-rotation | With/without |

| Screw Lead | 10,20mm | Load Connection Type | Male,female,U-bolt,ball Head Hinge And Customized |

| Highlight | electric rotary actuator,Fast Response Electric Linear Servo Actuators,2000mm Stroke Linear Servo Actuator |

||

50~2000mm Servo Electric Cylinder With Exclusive Software,Fast Response Linear Actuator

1. About Linear Servo Cylinder

It is also called Servo Electric Cylinder,a kind of actuator that achieves linear reciprocating motion through screw.It transforms the rotation motion of the servo motor into linear motion.

Servo linear actuator can transform the optimal advantages of servo motors(precise rotational speed control, precise rotation number control and precise torque control) into accurate speed control, accurate position control and precise thrust control.

As a new energy-saving transmission product, electric cylinder undoubtedly has more advantages in energy using and pollution control.

2. Electrical Servo Cylinder Drive Torque

And Power Selection Table

| Motor connection | Parallel (belt drive) | ||||||||||||||||||

| Reduction ratio | 1 | 1.5 | 3 | 5 | 10 | ||||||||||||||

| Screw Lead | [mm] | 10 | |||||||||||||||||

| Motor Power | [KW] | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | |||

| Motor Rated Torque | [N.M] | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | |||

| Motor Rated Speed | [r/min] | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | |||

| Cylinder Rated Force | [KN] | 9.25 | 14.56 | 19.84 | 13.88 | 21.84 | 29.76 | 27.75 | 43.68 | 59.52 | 46.26 | 72.8 | 99.2 | 92.51 | 145.6 | 150 | |||

| Cylinder Max. Force | [KN] | 150 | |||||||||||||||||

| Cylinder Speed | [mm/s] | 0-250 | 0-220 | 0-110 | 0-65 | 0-30 | |||||||||||||

| Motor connection | Linear (coupling direct drive) | |||||||||||||||||||

| Reduction ratio | 1 | 1.5 | 3 | 5 | 10 | |||||||||||||||

| Screw Lead | [mm] | 10 | ||||||||||||||||||

| Motor Power | [KW] | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | |||||||

| Motor Rated Torque | [N.M] | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | |||||||

| Motor Rated Speed | [r/min] | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | |||||||

| Cylinder Rated Force | [KN] | 9.25 | 14.56 | 19.84 | 27.75 | 43.68 | 59.52 | 46.26 | 72.8 | 99.2 | 92.51 | 145.6 | 150 | |||||||

| Cylinder Max. Force | [KN] | 150 | ||||||||||||||||||

| Cylinder Speed | [mm/s] | 0-250 | 0-220 | 0-110 | 0-65 | 0-30 | ||||||||||||||

| Motor connection | Parallel (belt drive) | ||||||||||||||||||

| Reduction ratio | 1 | 1.5 | 3 | 5 | 10 | ||||||||||||||

| Screw Lead | [mm] | 20 | |||||||||||||||||

| Motor Power | [KW] | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | |||

| Motor Rated Torque | [N.M] | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | |||

| Motor Rated Speed | [r/min] | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | |||

| Cylinder Rated Force | [KN] | 4.63 | 7.27 | 9.92 | 6.94 | 10.91 | 14.88 | 13.88 | 21.82 | 29.75 | 23.13 | 36.36 | 49.59 | 46.26 | 72.72 | 99.18 | |||

| Cylinder Max. Force | [KN] | 100 | |||||||||||||||||

| Cylinder Speed | [mm/s] | 0-250 | 0-220 | 0-110 | 0-65 | 0-30 | |||||||||||||

| Motor connection | Linear (coupling direct drive) | |||||||||||||||||||

| Reduction ratio | 1 | 1.5 | 3 | 5 | 10 | |||||||||||||||

| Screw Lead | [mm] | 20 | ||||||||||||||||||

| Motor Power | [KW] | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | 3.5 | 5.5 | 7.5 | ||||

| Motor Rated Torque | [N.M] | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | 16.7 | 26.25 | 35.81 | ||||

| Motor Rated Speed | [r/min] | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | ||||

| Cylinder Rated Force | [KN] | 4.63 | 7.27 | 9.92 | 6.94 | 10.91 | 14.88 | 13.88 | 21.82 | 29.75 | 23.13 | 36.36 | 49.59 | 46.26 | 72.72 | 99.18 | ||||

| Cylinder Max. Force | [KN] | 150 | ||||||||||||||||||

| Cylinder Speed | [mm/s] | 0-250 | 0-220 | 0-110 | 0-65 | 0-30 | ||||||||||||||

3. Construction Types

(1) Parallel& Linear

Linear:connect motor and ball screw directly by coupling

Parallel:Using synchronous belt and gear drive to connect motor and screw

(2) Comparison

Accuracy :Linear > Parallel

Parallel is more convenient for customer to mount

4. Applications

(1) Military equipment:radar, missile erector, armored vehicle swing platform, special equipment and other warships and aircraft hatch,opening, seat height adjustment, weapon tracking system,actuator,experimental lifting support, tank artillery high and low direction action adjustment, The push of rocket fuel, the opening of furnace door, etc.

(2) Special equipment:industrial automation production line, assembly line, logistics transmission, lifting platform, offset control, valve control, coordinate manipulator, mechanical equipment CT Kama knife, food and medicine industry, CNC machine tools, industry packaging machine, Automotive electronic press, textile equipment winding machine indexing, die position control, clamping, drilling, positioning.

(3) Experimental Equipment: Simulation platform, test bed, wave machine, testing equipment etc.

This type is especially suitable for :

servo pressing, motor assembly production line and you can also purchase our servo pressing software together.

5. Why choose us?

1. Compact structure and small dimension.

2. High rigidity, low inertness and fast response.

3. High reliability and long operating life.

4. Energy saving&less noise.

5. Convenient assembly and use,simple maintenance.