All Products

Servo Motor Stator Assembly Line for High Precision,Stator Core Assembly for Stable Operation

| Place of Origin | China |

|---|---|

| Brand Name | TJ |

| Certification | CE |

| Model Number | TJ-SP-01,05,10,20,30,50,70,100,150,200,250,300 |

| Minimum Order Quantity | 1 pcs |

| Price | negotiable |

| Packaging Details | non wooden box |

| Delivery Time | 5-6 weeks |

| Payment Terms | T/T,30% payment in advance,70% before delivery |

| Supply Ability | 20 pcs per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Machine Model | C-type/four-column Type/desktop Type | Control Forms | Touch Screen Type/computer Type |

|---|---|---|---|

| Pressure Range | 0.1~250KN | Max. Effective Stroke | 500mm |

| Pressing Mounting Speed | 0~35mm/s | Fast Forward/return Speed | 0~100mm/s |

| Max. Dwell Time | 3000s | Repeatablity | ±0.01 |

| Control Mode | PLC | Frequency | 50/60Hz |

| Noise Level | ≤75dB | Positioning Accuracy | 0.01mm |

| Power Source | Electric | Pressure Adjustment | Stepless |

| Pressure Holding | Yes | Pressure Range | 0-400kg |

| Product Name | Servo Electric Press | Repeatability | 0.02mm |

| Safety Protection | Yes | Speed Range | 0-1000mm/s |

| Stroke Length | 50-150mm | Voltage | 220V/380V |

| Weight | 1300KG | Capacity | 30T |

| Control System | PLC | Dimension | 1400x1400x1700mm |

| Model | SEP-30T | Motor Power | 2.2KW |

| Safety Device | Light Curtain | Shut Height | 250mm |

| Slide Adjustment | 20mm | Speed | 50-100SPM |

| Stroke | 50mm | Table Size | 400x400mm |

| Warranty | 1 Year | ||

| Highlight | Stator Core Assembly Line |

||

Product Description

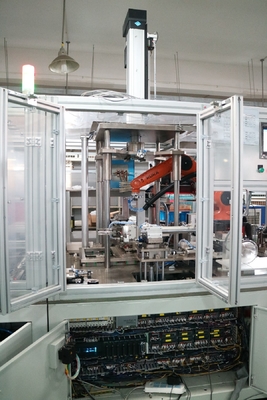

Servo Motor Stator Assembly Line for High Precision

A servo motor stator assembly line is a production line designed for assembling servo motor stators. Servo motors are commonly used in control systems and are known for their high precision, responsiveness, and stability, making them widely employed in industrial automation, robotics, CNC machines, and other applications.

The design of a servo motor stator assembly line typically involves the following main steps:

Parts preparation: The various components of the servo motor stator, such as stator coils, stator cores, bearings, end caps, etc., are prepared for the assembly process.

Stator coil assembly: Stator coils are mounted onto the stator cores, which often involves winding the coils into the core slots and ensuring correct positioning and fixation.

Stator core assembly: Assembled stator coils are then installed into their corresponding stator housings or frames, which requires precise alignment and securing.

Bearing installation: Bearings are mounted into the stator housing to support the rotation of the motor rotor.

End cap attachment: After stator assembly, end caps are installed to protect the stator and coils and secure the stator components.

Quality inspection: Throughout the assembly stages, quality checks are performed to ensure the components meet the required standards.

Dynamic balancing test: Once the stator assembly is complete, the motor undergoes a dynamic balancing test to ensure there is no significant vibration or imbalance during high-speed operation.

Final assembly: After all the stator components are assembled, the stator is integrated with other motor parts, such as the rotor and housing, to form the complete servo motor.

Trial run and debugging: The fully assembled servo motor undergoes a trial run and debugging process to ensure its performance and functionality are functioning correctly.

Final inspection and packaging: The assembled servo motor goes through a final inspection to ensure it meets the required quality standards. It is then appropriately packaged and prepared for delivery to customers or further applications.

The design of a servo motor stator assembly line takes into account factors such as production efficiency, product quality, safety, and the production environment. For non-standard customized assembly lines, specific production requirements are considered during the design phase. Such assembly lines are typically provided by specialized machinery manufacturers or equipment suppliers, and they work closely with customers to meet their specific needs.

![]()

![]()

Recommended Products