All Products

Motor Rotor Press Machine for Secure Assembly,Safe & Reliable Motor Rotor Press

| Place of Origin | China |

|---|---|

| Brand Name | TJ |

| Certification | CE |

| Model Number | TJ-SP-01,05,10,20,30,50,70,100,150,200,250,300 |

| Minimum Order Quantity | 1 pcs |

| Price | negotiable |

| Packaging Details | non wooden box |

| Delivery Time | 5-6 weeks |

| Payment Terms | T/T,30% payment in advance,70% before delivery |

| Supply Ability | 20 pcs per month |

Product Details

| Machine Model | C-type/four-column Type/desktop Type | Control Forms | Touch Screen Type/computer Type |

|---|---|---|---|

| Pressure Range | 0.1~250KN | Max. Effective Stroke | 500mm |

| Pressing Mounting Speed | 0~35mm/s | Fast Forward/return Speed | 0~100mm/s |

| Max. Dwell Time | 3000s | Repeatablity | ±0.01 |

| Control Mode | PLC | Frequency | 50/60Hz |

| Noise Level | ≤75dB | Positioning Accuracy | 0.01mm |

| Power Source | Electric | Pressure Adjustment | Stepless |

| Pressure Holding | Yes | Pressure Range | 0-400kg |

| Product Name | Servo Electric Press | Repeatability | 0.02mm |

| Safety Protection | Yes | Speed Range | 0-1000mm/s |

| Stroke Length | 50-150mm | Voltage | 220V/380V |

| Weight | 1300KG | Capacity | 30T |

| Control System | PLC | Dimension | 1400x1400x1700mm |

| Model | SEP-30T | Motor Power | 2.2KW |

| Safety Device | Light Curtain | Shut Height | 250mm |

| Slide Adjustment | 20mm | Speed | 50-100SPM |

| Stroke | 50mm | Table Size | 400x400mm |

| Warranty | 1 Year | ||

| Highlight | Reliable Motor Rotor Press Machine,Safe Motor Rotor Press Machine |

||

Product Description

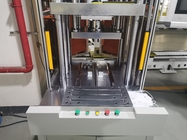

Motor Rotor Press Machine for Secure Assembly

motor rotor press machine, specifically designed for assembling the outer rotor of a motor onto a shaft with a tight fit. An outer rotor motor is a type of motor where the rotor is positioned outside of the stator. During the motor manufacturing process, it is essential to securely press the outer rotor onto the shaft to ensure proper functionality and performance of the motor.

The main features and characteristics of the motor rotor press machine include:

Press Force Control: The machine is equipped with a force control system that allows precise control of the pressing force. This ensures a tight and stable connection between the outer rotor and the shaft, preventing any looseness or detachment.

Automation: Modern machines often come with automation features, making the pressing process more efficient and accurate. Automation also increases production efficiency and reduces the possibility of human errors.

![]()

Suitable for Different Specifications: The machine is designed to accommodate various sizes and types of motor outer rotors and shafts, as different motor models may require different press configurations.

Safety Measures: Safety features are integrated into the machine to ensure the safety of operators. This may include protective covers, safety sensors, emergency stop buttons, etc.

Reliability: The pressing process significantly affects the motor's performance and lifespan, so the machine needs to be reliable to ensure consistent and stable pressing quality.

Data Recording and Feedback: Some machines are equipped with data recording and feedback capabilities, allowing the logging of pressing data for quality control and tracking purposes.

![]()

The motor rotor press machine plays a crucial role in the motor manufacturing process, ensuring that the motor meets the required quality and performance standards.

![]()

Recommended Products