All Products

Powerful Motor Manufacturing with Servo Electric Press, Servo Pressing for Enhanced Vacuum Cleaner Quality

| Place of Origin | China |

|---|---|

| Brand Name | TJ |

| Certification | CE |

| Model Number | TJ-SP-01,05,10,20,30,50,70,100,150,200,250,300 |

| Minimum Order Quantity | 1 pcs |

| Price | negotiable |

| Packaging Details | non wooden box |

| Delivery Time | 5-6 weeks |

| Payment Terms | T/T,30% payment in advance,70% before delivery |

| Supply Ability | 20 pcs per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Machine Model | C-type/four-column Type/desktop Type | Control Forms | Touch Screen Type/computer Type |

|---|---|---|---|

| Pressure Range | 0.1~250KN | Max. Effective Stroke | 500mm |

| Pressing Mounting Speed | 0~35mm/s | Fast Forward/return Speed | 0~100mm/s |

| Max. Dwell Time | 3000s | Repeatablity | ±0.01 |

| Control Mode | PLC | Frequency | 50/60Hz |

| Noise Level | ≤75dB | Positioning Accuracy | 0.01mm |

| Power Source | Electric | Pressure Adjustment | Stepless |

| Pressure Holding | Yes | Pressure Range | 0-400kg |

| Product Name | Servo Electric Press | Repeatability | 0.02mm |

| Safety Protection | Yes | Speed Range | 0-1000mm/s |

| Stroke Length | 50-150mm | Voltage | 220V/380V |

| Weight | 1300KG | Capacity | 30T |

| Control System | PLC | Dimension | 1400x1400x1700mm |

| Model | SEP-30T | Motor Power | 2.2KW |

| Safety Device | Light Curtain | Shut Height | 250mm |

| Slide Adjustment | 20mm | Speed | 50-100SPM |

| Stroke | 50mm | Table Size | 400x400mm |

| Warranty | 1 Year | ||

| Highlight | Powerful Motor Servo Electric Press,Vacuum Cleaner Servo Electric Press,Servo Electric Press Vacuum Cleaner |

||

Product Description

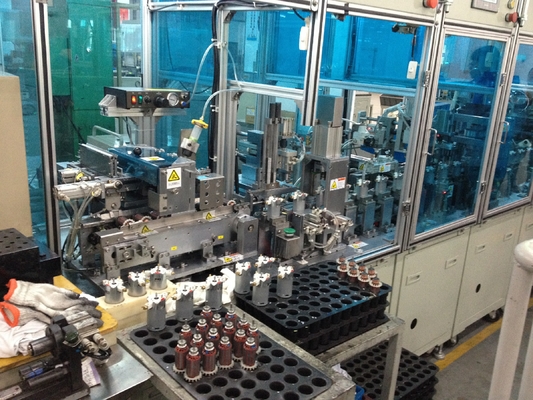

Powerful Motor Manufacturing with Servo Electric Press

Motor Manufacturing: The motor is manufactured and assembled at the beginning of the production line. This involves the installation of coils, shafts, and other motor components.

![]()

Vacuum Cleaner Assembly: Subsequently, workstations along the production line are used for assembling other parts of the vacuum cleaner, such as filters, dust containers, and the outer casing.

Servo Pressing: During the assembly process, servo press machines are employed. These machines are capable of precise control over pressure and positioning to ensure the proper installation of the motor and other components within the vacuum cleaner.

Quality Inspection: Completed assemblies may undergo quality inspections to ensure that each vacuum cleaner meets the required standards.

Packaging: Finally, the vacuum cleaners that pass inspection are packaged and prepared for shipment or retail distribution.

The primary goals of such a production line are to improve manufacturing efficiency, reduce manual labor, and ensure consistent product quality. The use of servo press machines enables accurate component installation, enhancing the reliability and performance of the final product.

Recommended Products